Electronic devices are becoming smaller, more complex, operate in different environments, and include several types of components that require tactile, optical, and electronic testing methods. The position of these devices in the final assembly demands precise positioning of the inspection tool in several degrees of freedom. PI offers powerful flexible motion systems for various test methods that can be integrated into customer production lines while maintaining capacity and throughput.

Key Features of PI’s Motion Systems

- Unique range of motion technologies to design most advanced solutions

- Industrial high-performance motion control platform provides coordinated motion of all axes for maximum throughput

- Easy connection and management of third-party sensors and test devices with flexible EtherCAT® connectivity

- Can be integrated as a subsystem under most PLCs and automation controllers

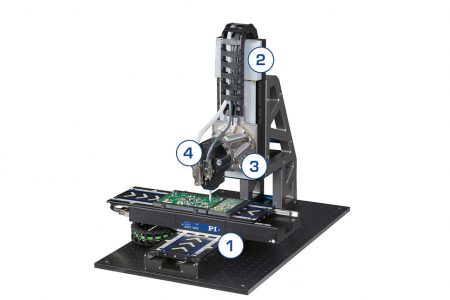

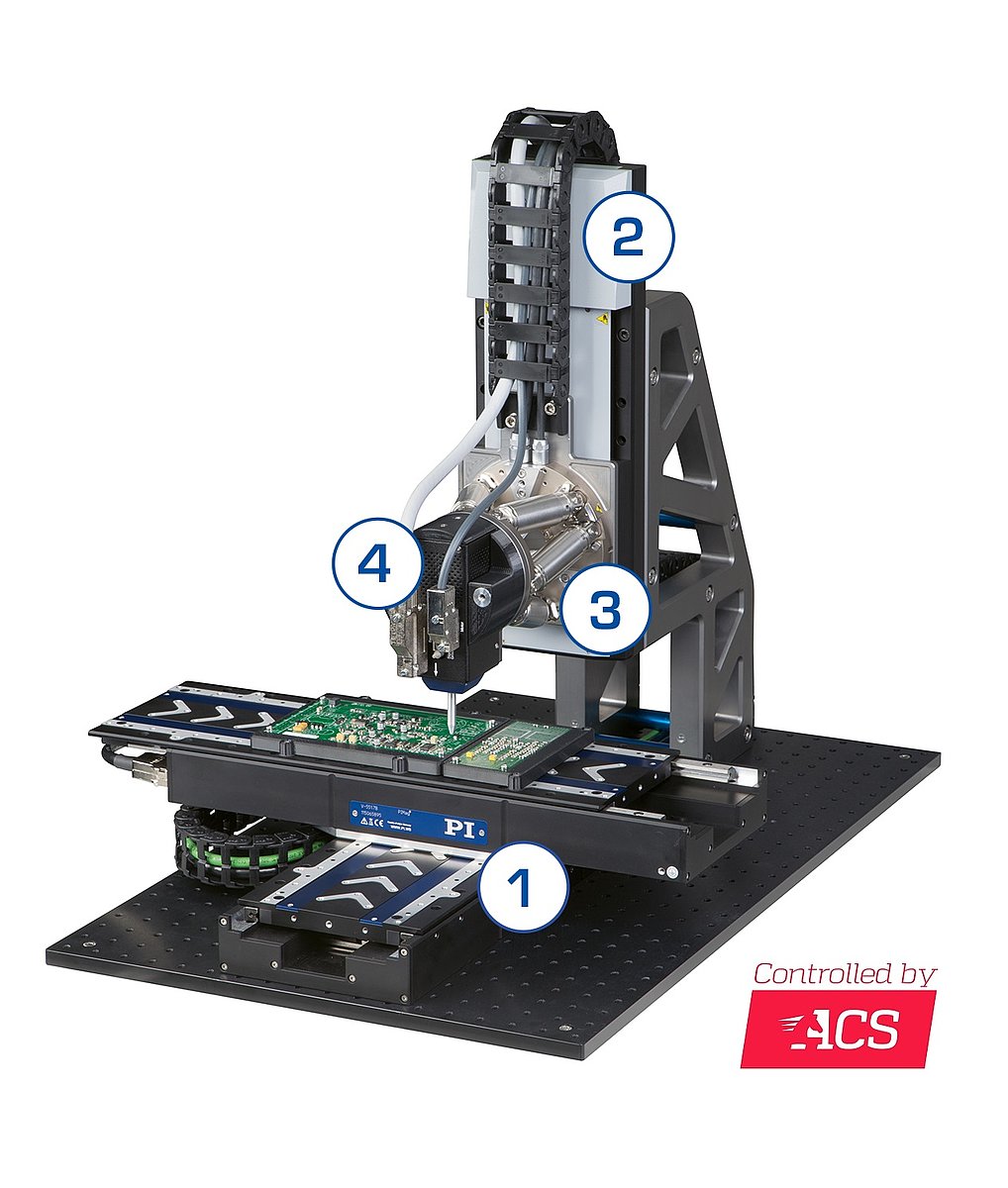

1. Workpiece Positioning

- Magnetic direct drive linear motors for high precision and high velocity

- Absolute encoder with 1nm resolution

- XY drag chain cable management

>> V-551 Precision Linear Motor Stage

2. Positioning of Testing Device

- Ball screw linear motor or voice coil stage

- Cable management integration

- Holding brake or counterbalance

- Direct-measuring linear encoder

>> M-511 High-Precision Linear Stage

3. Sensor Positioning at Various Angles

- Parallel-kinematic hexapod

- Six degrees of freedom

- Freely definable center of rotation

>> H-811 6-Axis Miniature Hexapod

4. Force Control of Measuring Sensor

- PIMag® voice coil linear actuator

- Force sensor with 1 mN resolution

- Weight force compensation

>> V-275 PIMag® Voice Coil Linear Actuator

Automation Control

ACS SPiiPlus EtherCAT-based motion control platform operates as an independent machine controller or as a subsystem under most PLCs and automation controllers

- Motion Controller >> SPiiPlusES

- Universal Servo Drives >> NPMpm

1. Workpiece Positioning

1. Workpiece Positioning