Simulating Camera Shake with High Precision

Obtaining razor-sharp images without using a tripod and at the same time, compensate for natural and artificial motion is currently one of the decisive factors for both cameras and smartphones. In cameras, sensors detect the shaking motion of the photographer or the vibrations of a vehicle or airplane so that the image stabilization system can compensate automatically. For this purpose, optical compensatory elements in the lens are shifted or the image sensor is moved. However, the corresponding algorithms and the mechanics must be optimized and tested. Parallel-kinematic Hexapods have proven to be very effective for the required highly dynamic simulation of defined precision motion.

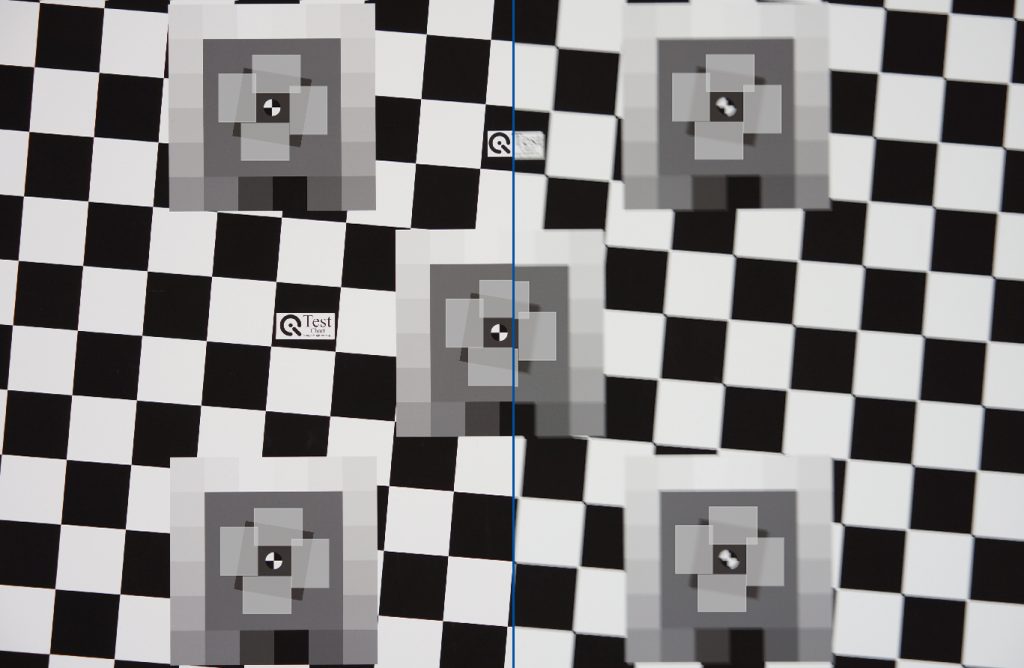

Image 1. Razor-sharp images even without using a tripod and at the same time, compensating for the natural shaking of the hand or the vibration of a vehicle are important requirements for modern camera systems. (Image: PI)

Those of you who have occupied themselves with photography are already familiar with the general rule of thumb concerning the relationship between focal width and exposure time: The crop factor for pictures in 35-mm format is the reciprocal value of the focal width of the lens used; with a steady hand, it is possible to take blur-free photographs with a 200-mm lens at an exposure time of less than 1/200 seconds. According to manufacturer specifications, the practical gain of image stabilization is up to four and a half aperture stops and that allows up to a 22-fold exposure time without shaking, when compared to systems that are not stabilized (Image 1). For example, when taking pictures of a firework display or atmospheric night scenes without flash, image stabilization really demonstrates its strengths, but it is also a great help for taking photographs under normal conditions.

More than Two Axes

An effective test procedure is of particular interest for both manufactures and users. And this is where Image Engineering plays a key role. Their core expertise is measuring the digital image quality as well as developing corresponding test procedures and comprehensive test systems for cameras.

Evaluating the image quality and testing the image stabilization place high technical demands on the test procedure and its components. Above all, the objective is precision simulation of the trembling, shaking human hand.

CIPA (Camera and Imaging Product Association), an alliance of Japanese camera manufacturers similar to an ISO committee, has developed the DC-011-2015 technical standard for defining the test conditions for motion simulation. It defines rotations around the Z and Y axes (pitch and yaw) as well as the test frequencies and oscillation amplitudes that are necessary for certification. This standard will shortly be adopted by an international ISO standard. However, the differences in motion behavior when using classical digital cameras and mobile devices such as telephones require the test procedure to be adapted to the individual circumstances of the smartphone user. “Now, camera manufacturers do not just correct motion on two axes as required by CIPA, but are increasingly calling for image stabilization on up to five axes.” explains Dietmar Wüller, Managing Director of Image Engineering. “Depending on the weight of the camera, shaking is different, and simulating two axes of motion does not provide significant test results anymore. The demands on smartphones are even higher. As a camera, they don’t fit well into the hand and when taking photos, they are often held at arm’s length or with the finger tips and in addition, the display is pressed to trigger the shutter, which tends to push it back”.

Parallel Kinematics Simulates Shaking

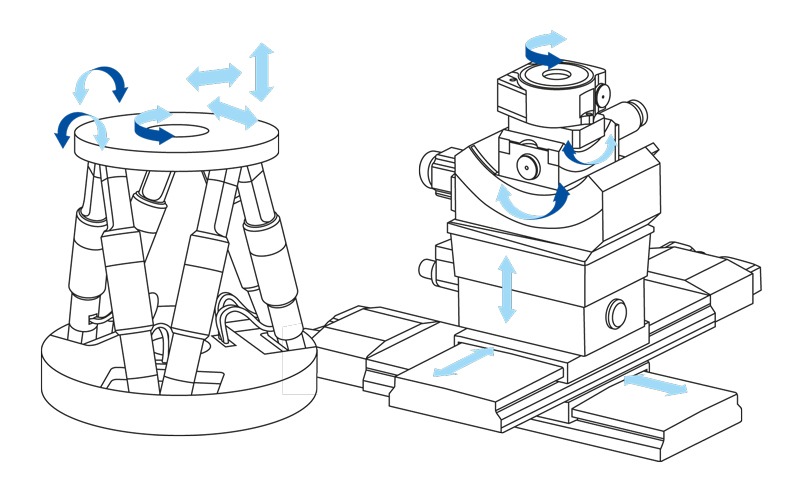

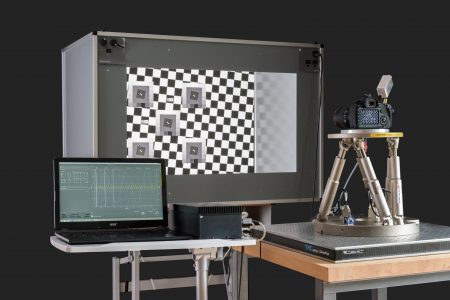

However, in the case of multi-axis test systems, the conventional, serial or stacked systems quickly reach their limits because of the accumulation of guiding errors. Parallel-kinematic systems are the best choice (Image 2). Above all, their advantages include considerably increased path accuracy, repeatability and flatness of travel as well as a lower moved mass that enables the same higher dynamic performance on all motion axes. Also, they don’t need complex cable management and the design is much more compact. “With the Hexapods from PI (Physik Instrumente), we have found a system that is particularly suitable for motion simulation, which can reproduce exactly defined “camera shake”; we were able to use and control it simply according to our specifications and test procedure”, reports Wüller enthusiastically.

Image 2. The Hexapods have a parallel-kinematic design; that mean, six drives act together on a single platform. (Image: PI)

“The frequency of human shaking goes up to 12 Hz, which means that the tests must be able to cover a range from 0 to 12 Hz. The bulk of the frequencies required is in the range between 4 and 8 Hz. Hexapods are predestined for this purpose.”

Different Weight Classes and Travel Ranges

As test systems, the image stabilization experts opted for two different Hexapods, depending on the weight of the test items and the travel range required.

Image 3. The H-811 mini Hexapod is used for example, in test systems for smartphones. (Image: PI)

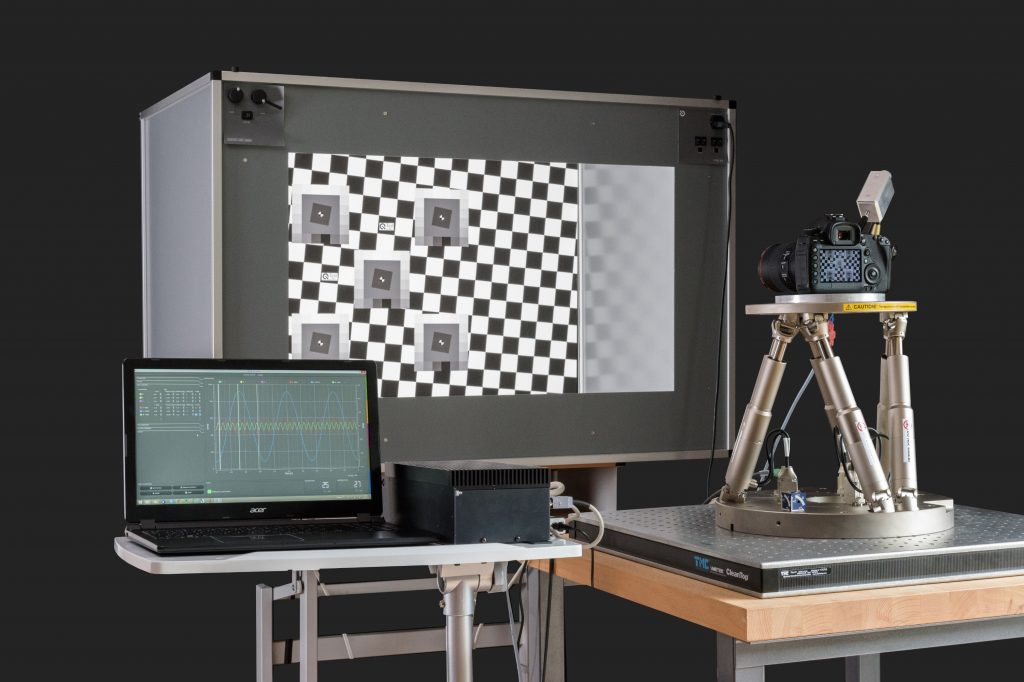

The H-811 mini Hexapod is used in test systems for smartphones (Image 3). The universal H-840 is used for heavier cameras or larger travel ranges (Image 4). Both of them are perfectly suited for testing image stabilizing systems and are already certified by CIPA. “The CIPA certification has enabled us to take on a pioneering role in the qualification of a six-axis system for evaluating image stabilization systems”, underlines Wüller.

Image 4. Setup with the STEVE 6D (Stabilization Evaluation Equipment) system for testing the image stabilization in a camera: The H-840 is used here. (Image: Image Engineering)

In the meantime, both Hexapods have proven themselves in practical use: The mini Hexapod can simulate vibration, e. g., rotary motion, with dynamics of 20 Hz and a deflection of 0.1°. For this purpose, the parallel-kinematic system performs a repeatable and defined test trajectory. It provides travel ranges up to 34 mm on the XY plane and up to 13 mm in the Z direction. The tilt angles are 20° around the X and Y axes and up to 42° around the vertical. The H-840 carries higher loads, provides travel ranges up to 100 mm and rotational angles up to 60°.

Easy Control and a Freely Definable Pivot Point

The high-performance C-887 digital controller takes care of the control for both Hexapods that, thanks to the user-friendly software, enables easy commanding. Positions are specified in Cartesian coordinates and transformations for the six individual drives takes place in the controller.

The freely definable rotation or pivot point is an essential feature of the Hexapod. This makes it possible to match the motion of the Hexapod platform directly to the respective camera and integrate it into the overall process. “This is the function for our test systems that we really like, because the camera system is not always positioned on the Hexapod so that the image sensor is at the center of all degrees of freedom.” explains Philipp Feldker, development engineer at Image Engineering.

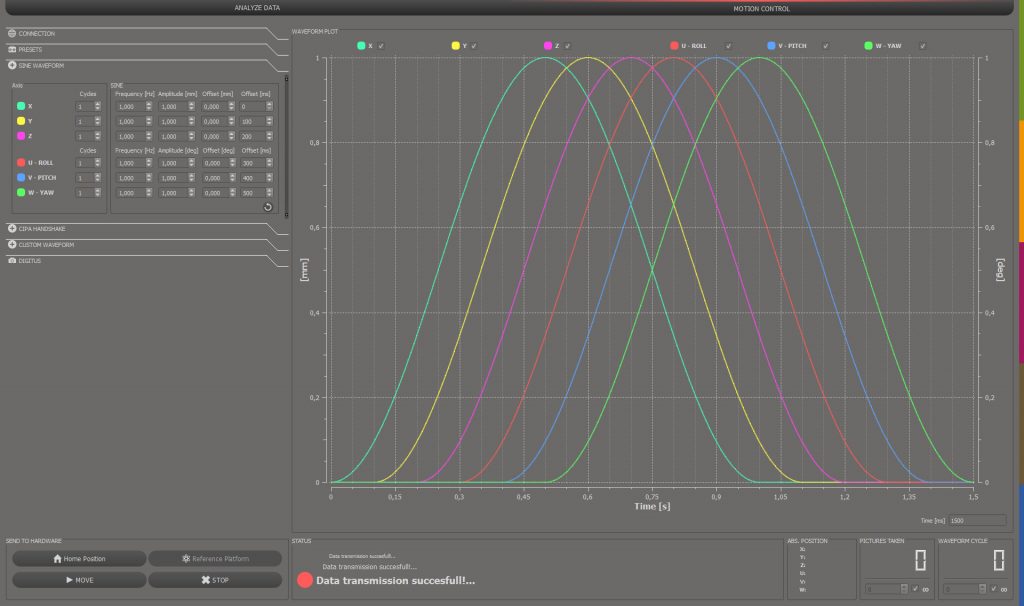

“Our test software then reads the data from the controller via the TCP/IP interface and adapts it as necessary”, adds Wüller. Thanks to the high sampling rate of the controller, it is also easy to create and transfer customer-specific test procedures with the software provided by Image Engineering (Image 5).

Image 5. A sine or a customer-specific motion with a different frequency and amplitude can be defined for each of the six degrees of freedom. (Image: Image Engineering)

What is Tested?

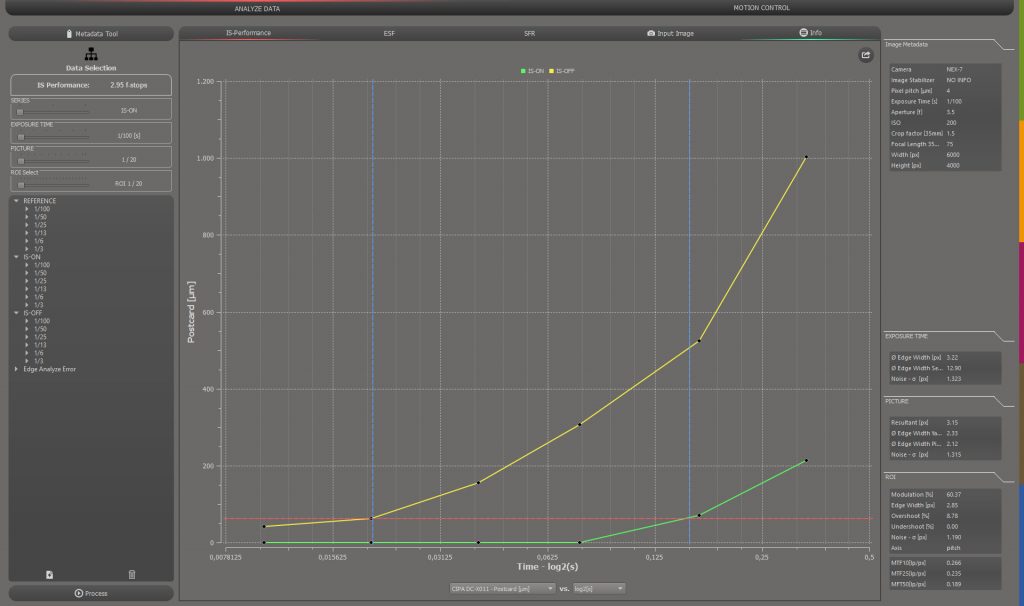

The Hexapod is fixed to a base plate for the tests. The camera holder and a so-called digitus, which is a mechanical finger for triggering the camera, is mounted onto its platform. An image of the full format test chart is acquired. Images of the test chart are acquired while the Hexapod shakes the camera according to the test trajectories. The motion blur is then analyzed from this (Image 6). The process is designed to test the behavior of the width of several diagonal edges at different exposure times with the motion control switched on and off. The image stabilization should be able to reduce shifts in the image (Image 7).

Image 6. After the Hexapod has moved the camera according to the test trajectories, the motion blur is analyzed and the performance of the image stabilization is output in aperture stops. (Image: Image Engineering)

Image 7. A test chart with (right) and without image stabilization (image: Image Engineering)

Image stabilization is not just designed for photography. Other examples come from the automobile industry, where such tests are useful for example, for automatic recognition of traffic signs, where reliable function is necessary under strong vibration or adverse lighting conditions. “The frequencies are actually higher, but it is even possible to set up a test procedure for this with the help of corresponding Hexapods,” adds Wüller finally.